Advanced 3D Printing. Precision, Speed, Quality

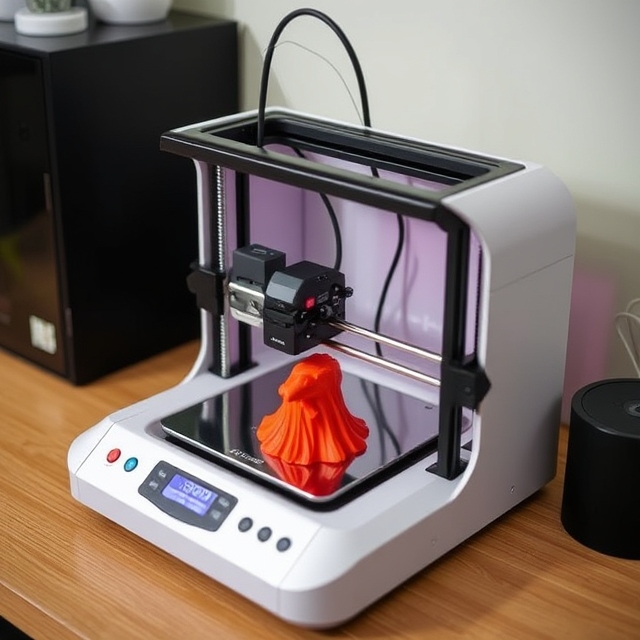

Fused Deposition Modelling (FDM) 3D printers, developed by the engineers at EBB Engineering Design and Consultancy Services, are cutting-edge additive manufacturing systems that enable the creation of objects layer by layer using thermoplastic filament.

FDM printers are well-known for their low cost, ease of use, and adaptability, making them an excellent choice for prototyping, manufacturing functional components, and developing unique designs in a wide range of sectors

FDM, an industry-leading technology, wide range of industries.

FDM 3D printers are used across a broad range of industries and applications, including

Rapidly creating prototypes for testing and evaluation, allowing designers and engineers to iterate quickly.

Manufacturing durable, functional parts for mechanical, automotive, and aerospace applications.

Offering a flexible solution for producing custom-made products, from small batches to large-scale production runs.

Teaching students the basics of 3D printing, engineering, and design through hands-on projects.

Transforming concepts into reality with cutting-edge technology and unmatched craftsmanship. From intricate designs to robust creations, we redefine possibilities in additive manufacturing."

Who are in extremely love with eco-friendly systems.

Prints up to 10 times faster than traditional 3D printers.

Capable of reaching speeds up to 500 mm/s for quicker print times.

Reduces print time by up to 65% when printing the same model.

Enhanced cooling for improved print quality and performance.

Allows you to control the printer anytime, anywhere, directly from your device.

Provides ample space for printing larger models.

Automatically adjusts the print bed for precise and consistent printing.

Equipped with an LED light for better visibility during printing.

Seamlessly controlled by Klipper for enhanced precision, faster printing speeds, and smoother performance.

The operation of an FDM 3D printer is straightforward and efficient, involving several key steps to transform digital designs into physical objects.

The process begins with feeding filament into the printer’s extruder. The filament comes in various materials such as PLA, ABS, PETG, and others, each with unique properties suited to different applications. It's loaded into the printer at the beginning of the print job.

Once fed into the extruder, the filament is heated to its melting point. The extruder melts the filament, turning it into a liquid state, ready to be deposited onto the build platform.

The printer follows the design specifications of the 3D model. The extruder deposits the molten filament in thin layers, carefully building up the object one layer at a time. The movement of the extruder head is controlled by the printer's software, precisely following the coordinates defined in the model.

After each layer is extruded, it begins to cool and solidify, bonding with the layer below. The cooling process helps the filament quickly set, enabling subsequent layers to be added on top without warping or separating.

This layer-by-layer deposition is repeated till the final layer of the part/object. The process continues until the 3D model is fully printed, with the printer building it from the bottom up, gradually turning the design into a tangible object.